Potato cleaning and peeling machine is a multifunctional potato processing equipment. It can not only clean potatoes, but also peel them for subsequent deep processing.

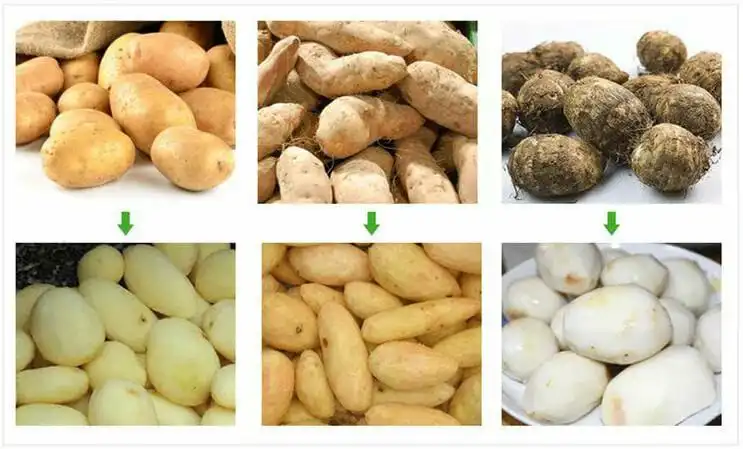

Free QuoteThe potato washing and peeling machine can wash and peel root vegetables at the same time, it is suitable for removing the thin skins of root vegetables such as potatoes, carrots, kohlrabi, and sweet potatoes.

Before

Potato washing and peeling machine is an indispensable potato washing and peeling machine for semi-automatic potato chip production line or automatic potato chip production line.

After

The potato washer and peeling machine can also work independently in restaurants, hotels and some other vegetable or food processing industries.It is the most convenient potato washing and peeling machine.

1. We have 3 types of potato cleaning and peeling machines for you to choose: brush roller type Potato Washing Peeling Machine, Screw & brush roller type Potato Washing Peeling Machine, Drum type Potato Washing Peeling Machine.

2. The output of the potato cleaner and peeling machine ranges from 300kg/hour to 3000kg/hour, which is suitable for any scale of potato chip production.

3. Our potato cleaning and peeling machine has a peeling rate of over 98%.

Our range of machines include the Brush Roller type, Screw & Brush Roller type, and the Drum type, all tailored to cater to a variety of processing requirements.

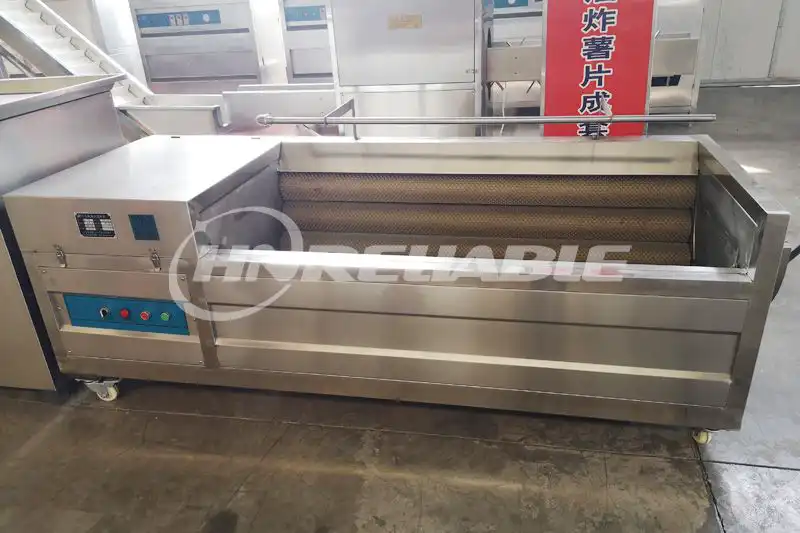

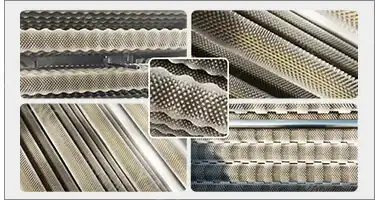

The Brush Roller Type machine harnesses the power of brush roller washing principles to effectively clean and peel a wide array of fruits and root vegetables. Crafted from food-grade 304 stainless steel, the machine features 9 pieces of roller brushes that can be customized as soft nylon brushes, hard nylon brushes, or emery rollers to accommodate different vegetables and fruits.

|

|

|

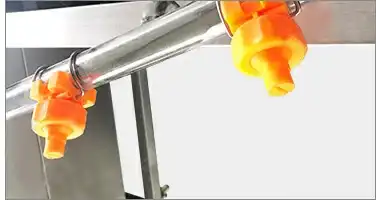

| Brush roller | Spraying nozzle | Moving wheels |

|

|

|

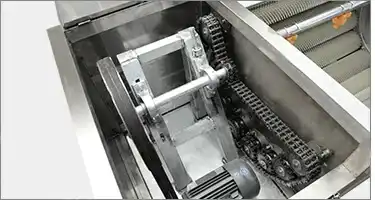

| Water inlet | Manual control discharge outlet | Transmission part |

The Screw & Brush Roller type integrates a spiral discharge and spraying device, offering robust cleaning capabilities for thorough washing and peeling of potatoes. This type also features the ability to adjust the speed and washing peeling time according

to your needs.

|  |  |

|---|---|---|

| Brush rollers with different shapes and sizes | Spiral device | Water tray |

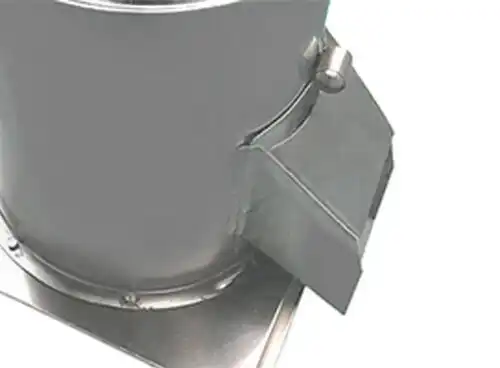

The Drum Type machine leverages emery grinding and centrifugal rotation technologies for high-efficiency washing and peeling. Ideal for small potato chips making businesses and small frozen french fries-making businesses, this machine is designed to handle

10-15kg of potatoes at a time.

|  |  |

|---|---|---|

| Superior quality emery for peeling | Discharge hole for peeled potatoes | Equipped with water-tap for washing potatoes easily. |

Besides potatoes, our versatile potato washing peeling machines can also wash and peel a variety of fruits and root vegetables such as carrot, radish, cassava, yam, taro, sweet potato, and beetroot. Furthermore, the brush type peeling machine proves effective

for fish scaling and seafood washing.

The machine is made from food-grade 304 stainless steel, ensuring it is safe and durable for food processing.

The machine has an impressively high peeling rate of over 98%, ensuring maximum yield from your produce.

Yes, our machine is versatile and can be used to clean and peel a variety of root vegetables and fruits, not just potatoes.

The machine features adjustable speed, washing and peeling times, offering great flexibility to adapt to your specific needs.

Yes, our machine is designed with durable wheels for easy movement and positioning in your workspace.

The machine's capacity ranges from 300kg/h to 3000kg/h, making it suitable for potato chips production of any scale.

Yes, while the machine is an integral part of semi-automatic and automatic potato chips production lines, it can also work independently in restaurants, hotels, and other food processing industries.

Yes, our potato washing and peeling machine is designed for easy cleaning to ensure hygiene and ease of maintenance.

Yes, we offer customized solutions to meet your specific requirements, from the type of brushes to the peeling and washing time.

The machine is equipped with a water tray to collect waste water, preventing water from flowing onto the ground and keeping your workspace clean and dry.

Leave a Message